A tank level gauge's capability to provide accurate readings is crucial. Calibration ensures the gauge provides readings that correspond accurately to the actual fluid level within the tank. Regular inspection and recalibration are indispensable to maintain accuracy over time, as gauges can be affected by factors such as temperature fluctuations, oscillation, and component degradation.

A well-calibrated tank level gauge provides dependable readings, allowing accurate inventory management and preventing possible issues such as overfilling or underfilling of tanks.

Streamlining Tank Inventory Management

Effective tank inventory management is paramount for enhancing operational efficiency and minimizing significant losses. Implementing a robust system entails meticulous implementation and integration of various components. A well-structured inventory management system should record instantaneous tank levels, forecast future requirements, and generate prompt alerts for refill needs.

- Key components of a tank inventory management system include automated level monitoring, integrated data platforms, and reliable reporting capabilities.

- Additionally, implementing barcode technology can streamline inventory tracking and precision.

- Regular system maintenance are vital to guarantee optimal effectiveness.

Leveraging Radar Technology for Precise Tank Level Gauging

In the realm of industrial process monitoring, accurate and real-time tank level gauging serves a crucial role. Traditional methods, such as displacers or float switches, often face limitations in terms of accuracy, reliability, and applicability. Radar technology has emerged as a compelling solution to overcome these hurdles, providing precise and non-invasive level measurement capabilities. Radar sensors emit electromagnetic waves that reflect off the surface of the liquid within the tank. By analyzing the time delay between the emitted signal and its reflected read more counterpart, the sensor can determine the distance to the liquid surface, thus providing an accurate level reading. The inherent advantages of radar technology include its ability to operate across a wide range of temperatures, pressures, and tank materials, minimizing maintenance requirements and ensuring consistent performance.

Innovative Tank Side Level Monitors: Design and Functionality

Tank side level monitors are vital instruments for accurately determining the liquid levels within tanks. These sensors have evolved significantly, incorporating advanced design features to enhance readability. Modern tank side level monitors often utilize ultrasonic or radar systems for contactless measurement, providing consistent readings even in challenging conditions.

Some designs feature combined display units, offering a clear view of the quantity directly on the tank exterior. This avoids the need for separate readouts, simplifying monitoring and operations.

The selection of an appropriate tank side level monitor depends on factors such as tankcomposition, liquidproperties, and demands}.

Refining Tank Monitoring Systems: A Comprehensive Guide

In today's complex industrial landscape, effectively monitoring tank levels is crucial. Implementing a comprehensive tank monitoring system improves operational efficiency, minimizes spills, and guarantees accurate data for informed decision-making. This guide provides a detailed exploration of best practices for optimizing your tank monitoring system, exploring key aspects such as sensor selection, data processing, and system deployment.

- Employing advanced sensor technologies to guarantee accurate tank level readings.

- Integrating reliable data transmission methods for real-time visibility.

- Automating data analysis and reporting processes for efficient insights.

- Implementing robust security protocols to secure sensitive tank information.

With implementing these guidelines, you can maximize the performance of your tank monitoring system, driving to increased operational efficiency, reduced costs, and improved safety.

Real-Time Data Acquisition with Tank Level Sensors

Monitoring tank levels in real time is crucial for a variety of processes. Precise data on tank content allows for streamlined operations, preventing situations where the tank is too full. Sensors designed to measure tank levels continuously provide valuable insights that can be employed for process control.

Hallie Eisenberg Then & Now!

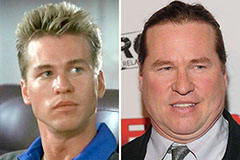

Hallie Eisenberg Then & Now! Val Kilmer Then & Now!

Val Kilmer Then & Now! Sam Woods Then & Now!

Sam Woods Then & Now! Daryl Hannah Then & Now!

Daryl Hannah Then & Now! Nicholle Tom Then & Now!

Nicholle Tom Then & Now!